What do you imagine when you picture yourself aboard a ferry that is transporting you across a body of water? Perhaps a rolling breeze? Nice, sunny weather and shimmering water? Scenic views? When the ride ends and the ferry is moored, do you imagine a smooth stop? Ferry operators are highly skilled at making your ride as smooth as possible, which is easiest to do when the weather is nice. When the weather turns sour and the winds pick up speed and larger waves form, precise navigation becomes harder to accomplish. This is where guide walls and structural dolphins come in handy.

Guide walls and dolphins exist to keep ferries and other large vessels on course. However, if the two types of structures are made with traditional materials (i.e. wood, steel or concrete), the ferry can be damaged upon impact as well as cause damage to the berthing structures - resulting in the need for maintenance or replacement.

Energy absorption is a key factor to focus on. Materials that can’t absorb much energy from a collision tend to break and experience significant wear over time. On the other hand, materials that can bend and recover without breaking can absorb much more energy. Watch as this ferry in Jamestown, VA collides with a single structural dolphin, which was made to bend to absorb the energy from the collision, and then recover from it.

As you can see, neither the ferry nor the structural dolphin were damaged. Dolphins like these, as well as guide walls that have the same energy-absorbing properties, are made from fiber-reinforced polymer (FRP). Many locations already use FRP to protect vessels and waterfront structures, such as at the Jamestown, VA Ferry, and at St. John’s River Ferry in Jacksonville, FL, who use FRP guide walls and dolphins.

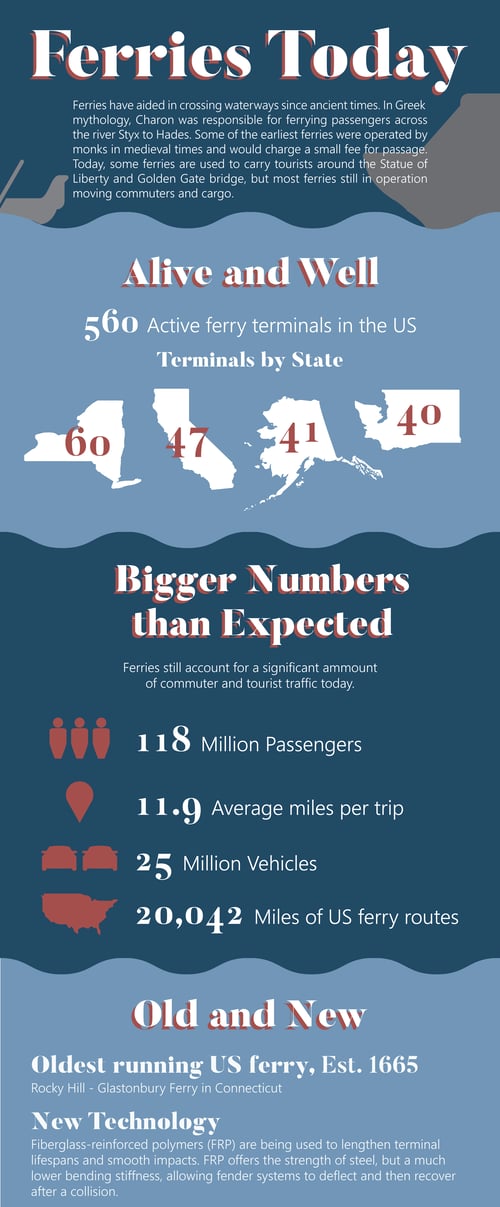

To get an even greater perspective at the number of ferry terminals in the U.S., take a look at our infographic below!

Impacts will inevitably happen. It is impossible to prevent high winds and strong currents, but you can prevent unnecessary damage from occurring. FRP is not only superior in energy absorption, it also significantly reduces the maintenance costs caused by collision damage and wear and tear.

If you are interested in learning more about FRP for a future project, we’d love to talk with you about it. Feel free to contact us with any questions or comments you may have.