To steel or not to steel - that is still the question.

We always say "to steel," at least when designing FRP bridges and considering the high structural loads of infrastructure applications. Our FRP products include embedded steel sections to handle concentrated loads, especially at high load attachment points. FRP structures are highly effective when it comes to uniform loads and distributing loads among the rest of the structure. FRP’s high strength properties are comparable to steel, and FRP can be tailored for primary load directions. However, attachment points where loads are introduced or reacted require the mechanical properties of bearing strength and thread strength. In short - steel.

Using steel inside the FRP structure distributes concentrated load to the surrounding FRP panel. In FiberSPAN decking, any site that involves bolted load transfer uses steel. This includes connections to the superstructure; rail posts, lamp posts and expansion joints. As part of the layup process, steel sections are primed to promote chemical bonding of the resin to the steel during the molding process. As fiberglass fabric and internal core are laid up in the molding tool, steel sections are included where connections will be located. Steel sections can be plate, angles or box tubing depending on load type and magnitude. The FRP panel houses the steel to maximize load distribution from steel to FRP and protect the metal from corrosion.

One example is the steel plates that are located inside the bottom facesheet of the decking to connect the deck to the superstructure. Holes are drilled and tapped into the fiberglass and steel plate following molding. When the deck is installed, clips are bolted to the superstructure by engaging these holes.

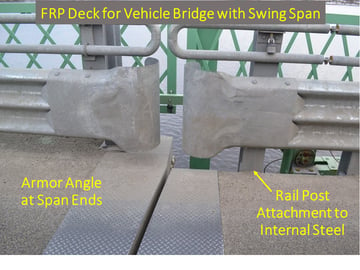

A second example are rail posts. Generally, a substantial amount of load needs to be reacted at the post attachments, especially for vehicle bridges. The FRP facehseet does not have the bearing strength, thread strength or moment capacity for these loads. So, a steel box tube replaces the internal core. The tube section easily handles the bolt loads and the section transfers the loads to the FRP facesheets and core. The tube size and length is determined by the amount of load to be sheared into the FRP.

A final example is the top corner of the deck panel at the ends of the bridge span. When trucks enter the bridge, they can impact the end panel hard. To prevent damage to the FRP over time, a steel angle is embedded at the panel corner with one leg under the top surface and one leg under the vertical edge.

Designers don't have to choose between FRP and steel, as they can incorporate the best of both materials.