If you work in an industry like wastewater treatment, paper and pulp manufacturing, oil and gas, chemical manufacturing, or another setting where storage and process tanks are common, you’re probably familiar with fiberglass reinforced plastic, or FRP, tanks.

If you work in an industry like wastewater treatment, paper and pulp manufacturing, oil and gas, chemical manufacturing, or another setting where storage and process tanks are common, you’re probably familiar with fiberglass reinforced plastic, or FRP, tanks.

Their strength and resistance to corrosion make them a versatile solution with a long useful life – exactly what you want from a capital investment.

But that durability means if you need a new tank, it may have been a while since you’ve had to write specifications for one. Here’s a quick review of materials and construction to help with your next new tank project.

Glass fibers

Glass fibers give finished FRP tanks and structures their strength due to their high tensile strengths. While E and C glass are commonly used in fiberglass tank applications, there are several options, depending on what’s needed, for example:

Glass fibers give finished FRP tanks and structures their strength due to their high tensile strengths. While E and C glass are commonly used in fiberglass tank applications, there are several options, depending on what’s needed, for example:

- E glass is electrically resistant and commonly used in FRP applications

- ECR glass combines strength, electrical resistance, and corrosion resistance

- C glass is resistant to corrosion and used in acidic applications

The fibers used in FRP structures are also called glass roving – very thin strands of glass that are made into different products:

- Woven fiber cloth comes in different thicknesses and weights and is measured in ounces per square yard.

- Chopped-strand mat is made of roving, often E or ECR glass, and held together in a matrix with a thin layer of sizing/binder resin to provide structure. It’s measured in ounces per square foot.

- Gun roving is a continuous strand of roving fed into a chopping gun for spray applications.

- Filament winding roving comes in varying weights, measured in yards per pound, and ranges from just under 100 yards per pound to several hundred yards per pound.

Resins

Resins provide corrosion resistance and help to distribute loads among the glass fibers in the finished FRP matrix. There are many options, depending on the composition and concentration of a tank’s contents as well as if it will be used for storage, mixing, scrubbing, or another purpose.

Many resins are forms of polyester or vinyl ester, with specific chemical compositions to withstand corrosion, heat, fire, or other conditions. Examples of common types of resins include, but are not limited to:

- Bisphenol epoxy vinyl ester, which is very strong and durable and withstand changes in temperature well.

- Epoxy novolac vinyl ester, which may be used with acidic solvents.

- Bisphenol fumarate polyesters, which are used for high-temperature applications (over 300 degrees Fahrenheit) and when rigidity is needed.

- Bromated polyester and vinyl ester resins, which have thermal resistance and flame-retardant properties.

- Terephthalic and isophthalic polyester resins, which are used for lower temperature applications (under 200 degrees Fahrenheit) and lesser acidic or basic pHs.

Along with resin selection, fabricators can include different types of resin additives to control the curing process and optimize the finished tank for environmental or use conditions. Common additives include:

- Promotors to influence cure characteristics such as the speed of drying. Many vinyl esters do not contain promotors in order to allow fabricators to customize the properties of a resin to the needs of the application.

- Initiators/catalysts to start the resin gelling process.

- Accelerators to speed up chemical reactions and cure time.

- Inhibitors to slow or extend gel time.

- synergists, including antimony oxides, to control fire retardancy and flame spread.

- UV absorbers to protect tanks from damage caused by exposure to UV rays from the sun.

- Color pigments for aesthetic or functional purposes (e.g. reducing heat absorption).

Fabrication

Construction methods of FRP tanks and structures fall into two main categories: hand lay-up and filament winding.

Hand lay-up includes placing layers or plies of thin woven fiber on a mold or spraying chopped fiber on a mold with a handheld gun applicator. Each layer is laminated with resin and air bubbles are rolled out to avoid creating air pockets (also called voids) developing during curing. Large tanks or structures can be fabricated as a single unit or in panels that are later joined, similar to how a barrel is constructed. This can be helpful when tanks are assembled on-site indoors or in areas with space restrictions.

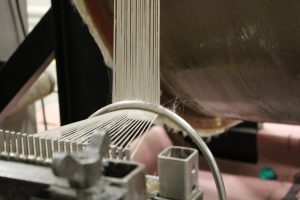

Filament wound tanks are fabricated by winding strands of glass roving around a rotating spindle, usually on a diagonal. The diagonal angle can be adjusted to optimize hoop strength (i.e. the strength around the circumference of the tank) and axial strength (i.e. end to end, often vertically). Several thin strands are usually held together, similar to rope or yarn, and the weight of the roving used depends on the application. The maximum diameter of a filament wound tank is determined by the size of the fabricator’s spindle.

Thin surface veil cloth can also be added for reinforcement against corrosion and UV exposure. Usually made of C glass fibers, surface veiling can be added to the inside or outside of a tank.

Accessories and other tank features

Tanks can be accessorized depending on the application. Options include the following, some of which we’ll discuss more in a future blog:

- manways or access ports to gain entry or clean out the tank

- inlets, outlets, and couplings for pipes

- ports for gauges and instrumentation (and supports for this equipment)

- flanges and tie-down lugs

- vents and covers

- drains, siphons, and weir plates

- internal mixing equipment

- heating and cooling coils

- nozzles and supports

- ladders, handrails, and walkways

It’s all in the details of your application

Your fabricator will review your specs and the details of your application, clarifying goals, and possibly suggesting alternatives to achieve the balance of longevity and cost. Details to describe include things like:

- temperatures

- external from the environment

- anticipated internal temperature fluctuations due to process conditions, mixing of chemicals or maintenance/cleaning procedures

- rate of temperature change anticipated (fast changes can compromise resin and structure integrity and corrosion resistance)

- pressure and hydrostatic load

- environmental conditions such as indoor or outdoor setting and UV exposure

- common name and chemical name

- pH of contents and anticipated changes to it

- concentration and chemical composition of contents

- specific gravity of contents

- process description including agitation or other process conditions

- pressure/vacuum conditions, especially if the tank will be filled with a pressurized system,

- flow rates

- fire retardancy requirements

One final tip: communication is the key. The more you can tell your FRP fabricator about tank content, use, and conditions the better they can customize tank to meet your unique situation. Contact us to discuss your new tank needs today!