Featured Project: St. Johns River Ferry Terminal

FRP guide walls make Jacksonville ferry terminals a soft landing

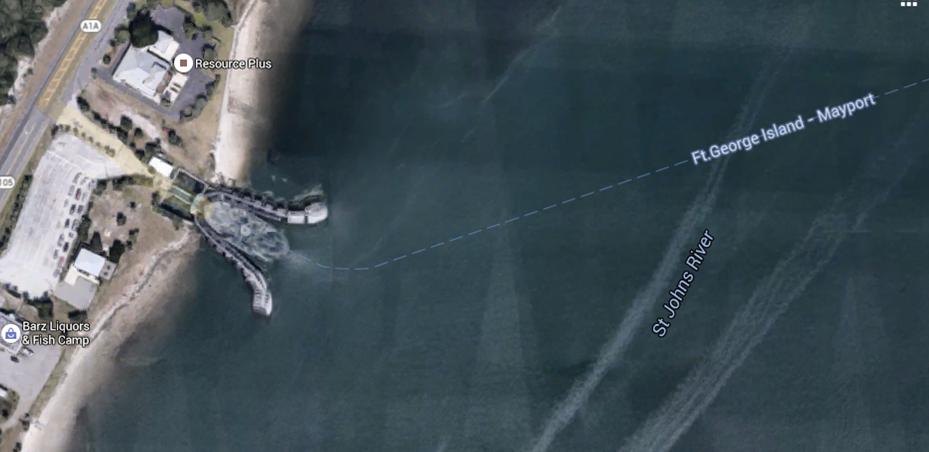

In the late 1800s, ferry service across the St. Johns River probably consisted of little more than a large wooden raft pulled by cables—its’ passengers people, animals and wagons. Today the St. Johns River Ferry moves cars and passengers back and forth between Mayport and Fort George Island. The 0.9 mile voyage departs every half hour.

The Jacksonville Transportation Authority (JTA) secured funding for upgrades that included new terminal structures and took over operation of the St. Johns River Ferry in March 2016. Aggressive currents and strong winds can make berth operations very difficult. The JTA needed energy absorbing guide walls to address these challenging conditions.

The existing steel and concrete fender wall guiding the ferry into its slip was repeatedly subjected to hard hits. Steel and concrete are by nature very stiff resulting in hard landings which sometimes resulted in damage to the vessel and the guide wall and compromised passenger safety.

The JTA considered different alternatives with the primary goal to find a low maintenance fender guide wall system that would also provide greater energy absorption. Durability, flexibility, low maintenance and corrosion resistance made FiberPILE the material of choice. The energy absorbing system reduces fender wall damage and improves safety and comfort, allowing passengers to enjoy the ride.

FiberPILE large diameter pilings are constructed using high-strength, directional fiberglass materials and a resin system formulated to withstand the most corrosive environments. The combination results in a maintenance free piling product that is ideal for protecting structures from the impact of barges and ships.

Standard FiberPILE diameters range from 24 inches to 48 inches and can be fabricated in continuous lengths up to 100 feet. Because FiberPILE uses fewer, large diameter pipe piles, installation costs are reduced. FiberPILE products can be driven with conventional pile driving equipment including both impact and vibratory hammers. FiberPILE can be cut, drilled, and connected using standard tools and hardware.

Standard FiberPILE diameters range from 24 inches to 48 inches and can be fabricated in continuous lengths up to 100 feet. Because FiberPILE uses fewer, large diameter pipe piles, installation costs are reduced. FiberPILE products can be driven with conventional pile driving equipment including both impact and vibratory hammers. FiberPILE can be cut, drilled, and connected using standard tools and hardware.

FiberPILES are driven into hard soils including wood piles from previous installations. The horizontal wales are composite timbers bolted to the piles and distribute impact loads to the piles. FRP channels splice the sections of timber together. Caps cover the hollow piles and become the base for navigation lights.

In summary, benefits of FRP waterfront protection systems constructed with pipe piles include high strength, superior energy absorption, low driving friction, dimensional stability and high impact resistance.

Project Details

PILING COUNT:

48 (Phase 1), 40 (Phase 2)

PILING DIAMETERS:

24 and 36 in

PILING LENGTH:

60 to 100 ft

PILING WALL THICKNESS:

1, 1.25 and 1.5 in

INSTALLATION METHOD:

Vibration hammer

WALE TYPE:

Reinforced plastic lumber

WALE SPLICES:

FRP C-channel

SPECIAL REQUIREMENTS:

Superior energy absorption

No maintenance

Corrosion resistance

Stability in high winds and currents

Recoverable deflection

Low driving friction

OWNER:

Jacksonville Transportation Authority

INSTALLATION DATE:

March 2016, March 2017

ENGINEER OF RECORD:

Morales Consulting Engineers

CONTRACTOR:

C&D Construction, Inc.