Material Selection

What is FRP Material?

Fiber-Reinforced Polymer (FRP) composite materials are highly durable, lightweight materials used in many industries, including wastewater treatment, chemical processing, military, mining, architecture, agriculture, infrastructure and more. One of the biggest benefits of FRP is its versatility. It is available in many different combinations of reinforced fibers, resins and additives, each of which offers its own unique advantages that make it suitable for different applications.

FRP refers to a polymer that has been reinforced with fibers such as glass fibers, carbon fibers, polyester fibers and natural fibers. When these fibers are combined with resins, the composite takes on new characteristics that improve its overall functionality and quality. These characteristics include strength, stiffness, corrosion resistance, reduced thermal conductivity, electrical insulation and more.

FRP refers to a polymer that has been reinforced with fibers such as glass fibers, carbon fibers, polyester fibers and natural fibers. When these fibers are combined with resins, the composite takes on new characteristics that improve its overall functionality and quality. These characteristics include strength, stiffness, corrosion resistance, reduced thermal conductivity, electrical insulation and more.

FRP exhibits many beneficial qualities that make it a suitable alternative to more traditional construction materials such as wood, steel, concrete and aluminum. For example, it offers the same strength as steel, but at a fraction of the weight. FRP is also durable, easy to manufacture and install, affordable, flexible, low maintenance and a great insulator. These properties make FRP a popular choice for a wide range of applications, both indoors and outdoors.

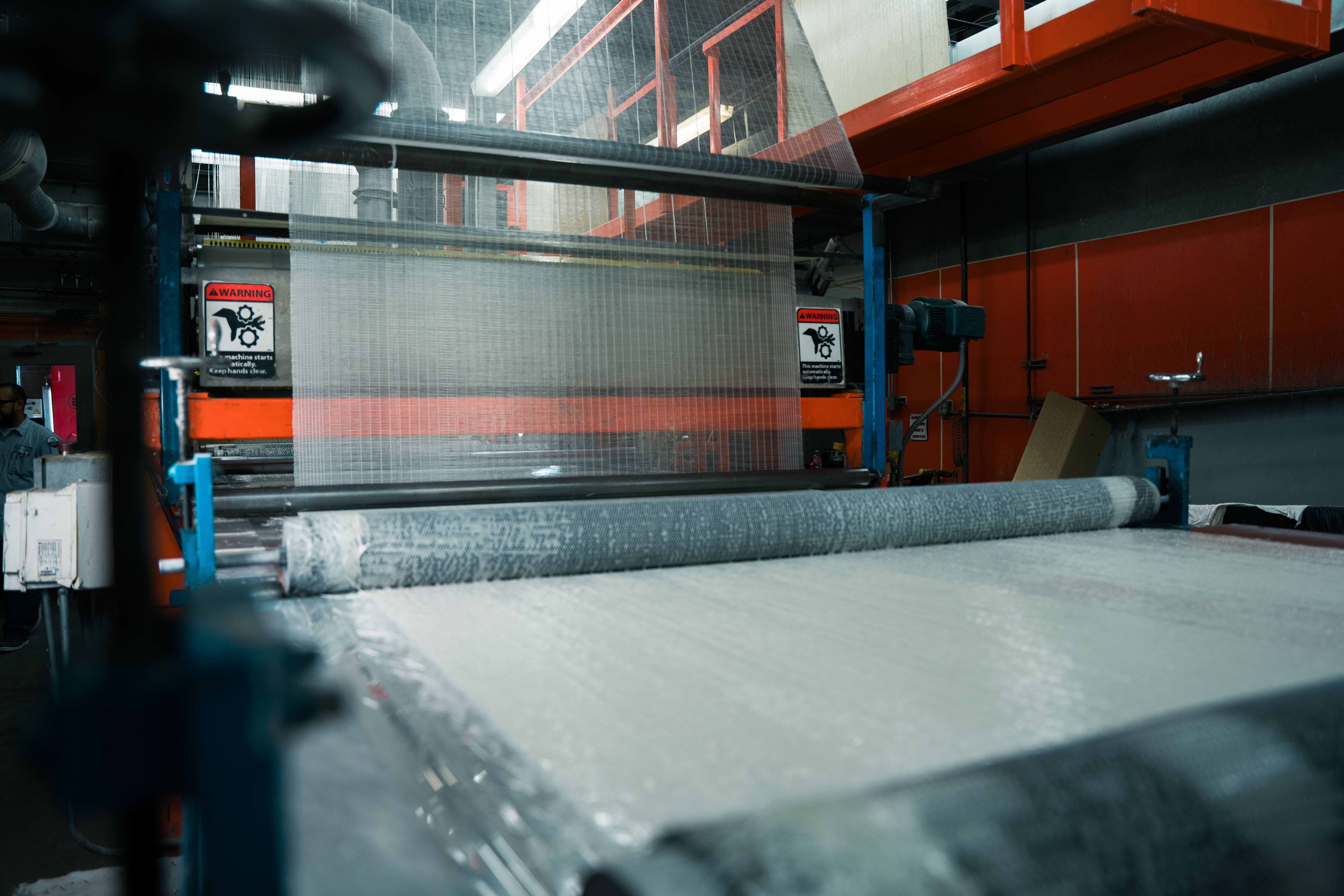

There are several ways to manufacture FRP, depending upon the finished product's size, function and aesthetics, as well as the volume of the order.

FRP PULTRUSION

FRP VACUUM INFUSION

FRP FILAMENT WINDING

FRP CONTINUOUS LAMINATION

Types of FRP Material

Isophthalic Polyester Resin

Vinyl Ester Resin

Polyurethane Resin

Phenolic Resin

FRP Resin Selection

Creative Composites Group offers products using all these materials.

Pultruded profiles are made from three standard resin systems: Isophthalic Polyester, Isophthalic Polyester Fire Retardant and Vinyl Ester Fire Retardant. Polyurethane is used in custom profiles. Vinyl esters and phenolics are used for infused products and infrastructure. Which one you choose for your project heavily depends on the service conditions of your application. Key factors to consider when selecting the appropriate resin include:

- Infrastructure

- Industrial Applications

- Temperature

- Humidity

- Chemical Contact

- PH Levels

- Corrosion Risk

- Direct Fire Exposure

- Ballistics

- Storm Hardening

- Grid Hardening

FRP Materials from Creative Composites Group

With an engineered combination of resin, fiber and additives, you can create the FRP material that's best for your application. To ensure your product performs optimally for as long as possible, it's essential to make informed choices about materials and processes.

Creative Composites Group is a team of U.S.-based composites companies dedicated to offering the best engineered solutions for our clients. With years of experience customizing FRPs for a wide range of applications, we can help you determine the best materials and manufacturing process to meet your unique needs. Contact us today to learn more about our FRP solutions, or request a quote for your next project.